Using the correct wooden packaging material helps to limit the spread of wood pests.

To prevent the spread of wood pests, wooden pallets used in trade across the European Union borders must be treated in accordance with the International Plant Protection Convention (IPPC) ISPM 15 standard and marked with a compliance mark to identify their origin.

Regardless of the treatment method used, the pallets must be made of debarked wood. The standard allows for separate and clearly distinguishable small pieces of bark if they are:

- less than 3 cm wide (regardless of length), or

- or wider than 3 cm if the total surface area of a single piece of bark is less than 50 cm²

Although pallets consist of several different components, they are considered a single unit and marked accordingly. Preferably on two opposite sides. Pallets can be made from both treated wood and treated wood-based materials that no longer require treatment. For example, pressed sawdust cubes and plywood.

Heat Treatment (Treatment code on mark: HT)

Wooden packaging material is heated according to a time-temperature graph, whereby a minimum temperature of 56°C is maintained for 30 consecutive minutes throughout the entire profile of the wood, including the bark.

Reuse of Heat-Treated Packaging Material

Wooden packaging material that has been treated and marked in accordance with ISPM 15 and has not been repaired, refurbished or otherwise altered does not require repeated treatment or marking during its service life.

In case of reprocessing, all previous markings must be removed (e.g., by painting over or sanding). After reprocessing, a new marking must be applied in accordance with the standard.

Repair of Heat-Treated Packaging Material

When repairing heat-treated packaging material, up to one-third of it or its components may be replaced. When repairing, it must be ensured that only heat-treated wood is used for repairs. If treated wood is used for repair, each added part must be individually marked in accordance with this standard.

Wooden packaging material bearing multiple different markings may cause problems in determining the origin of the wooden packaging material and, therefore, countries may limit the number of different markings and require the removal of previous markings, reprocessing, and then the application of a new marking when repairing wooden packaging material.

Refurbished Wooden Packaging Material

If more than one-third of the wooden packaging material or its components have been replaced, the packaging material is considered refurbished.

All previous markings must be removed from the refurbished wooden packaging material. The packaging material must be reprocessed and then re-marked.

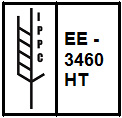

Marking and its Use

The size, font and position of the mark may vary, but its size must be sufficient to be clearly visible and legible to inspectors without the aid of any tools. The mark must be rectangular or square and located within a border, in which a vertical line separates the IPPC symbol from the other components. The compliance mark must be:

- Single-colored

- Clearly distinguishable and legible

- Water and wear resistant

- Non-removable

The compliance mark must not use red or orange colors. These colors are used to mark dangerous goods. The compliance mark must not be hand-drawn.

The compliance mark shall:

- The internationally recognized logo (a wheat head with an IPPC mark)

- EE-state symbol (ISO two-letter country code)

- 3460- numbers is the unique identification mark of the wood treatment agent or packaging manufacturer.

- HT- type of treatment, and will either be HT (Heat Treatment) or MB (Methyl Bromide)